infra CONVERT

blue DAT • infra DAT

mdm TOOL

infra CONVERT

blue DAT • infra DAT

mdm TOOL

User manual infra CONVERT > Settings > Settings

Settings can be modified on the Characteristics tab of the Settings menu, which influence the recognition of characteristics. Applied settings can be confirmed with OK or Apply, or discarded with Cancel.

Content

• Invoke

• “Common” group

• “Stamp number” group

• “Format characteristic title” group

• “Numerical precision” group

• “Number format” group

• “Attributive characteristic” group

• “Variable characteristics” group

• “Word specifications” group

• “Measurements without tolerance entry at nominal dimension” group

• “Limit values in one direction (min., max.)” group

• “Characteristics with nominal dimensions zero” group

• “Angular measurements” group

• “Dimensions with details of repetitions” group

• “Auxiliary dimensions” group

• “Theoretically precise measurements” group

• “Shape and positional tolerances” group

• “Radii” group

• “Chamfer” group

• “Edges with indeterminate shape” group

• “Surface parameters” group

• “Simplified indications” group

The menu can be invoked as follows:

Menu bar

Click on Edit and then on Settings in the drop-down menu that opens. The Settings menu window opens. Select the Characteristics tab in the list on the left side of the window.

Note Name of the settings group up to version 2.7.13: “Characteristic settings

| Option | Function | Default setting | |

|---|---|---|---|

| | A characteristic can contain several tags | Specifies that several tags can be assigned to a characteristic. | |

| | Ask before deleting characteristics | Specifies that a confirmation prompt must be confirmed before finally deleting a feature. Note Available from programme version 2.8.0. | |

| Option | Function | Default setting | |

|---|---|---|---|

| | Start value | Sets the default number which is to be initially assigned when stamping. | 1 |

| | Increment | Sets the increment of the characteristic numbers to be assigned. This value forms the difference between one stamp number and the next. | 1 |

| | Set minimum Number of Digits | Sets the minimum number of digits with which the stamp number is displayed in stamp texts. Missing digits are filled with zeros, example: If three digits are given, a “1” becomes a “001”. Note Available from programme version 2.6.1. | |

| | Set minimum Number of Digits | 3 | |

| Option | Function | Default setting | |

|---|---|---|---|

| | Variable characteristics | Defines how the title is formed for characteristics of type Variable. | {CL} {CLSY} {N} {M} {REF} |

| | Attributive characteristics | Defines how the title is formed for characteristics of type Attributive. | {CL} {TXT} |

| | Characteristic title per class | Defines how the feature title should be formed for selected classes, regardless of type. A new line can be added with Create ( Note Available from program version 4.1.0. | Word specification: {TXT} |

Rules for the structure of the title formatting

The variable letters described below are enclosed in curly brackets: {…}. The order can be chosen arbitrarily. Spaces are recommended as separators. Successive blanks are combined into one blank. Variables that are not set will not be exported. Any text characters can be used next to the variables; these are always displayed in the title.

| Variable {…} | Content |

|---|---|

| CL | Characteristic class |

| CLSY | Class symbol |

| TXT | Value |

| N | Nominal dimension |

| UT | Upper tolerance value |

| UT+ | Upper tolerance value, positive dimensions marked with a plus sign |

| LT | Lower tolerance value |

| LT+ | Lower tolerance, positive dimensions marked with a plus sign |

| F | Tolerance class or fit |

| M | Upper or lower limit |

| TXT | Value |

| REF | Reference |

| CON | Modifiers |

| C | Comment |

| REP | Number of repetitions in the form ”(2x)“, ”(3x)“ etc. |

| SPC | Extra space (will not be deleted if duplicated) |

| Option | Function | Default setting | |

|---|---|---|---|

| Converted results (Degree, Minute, Second to decimal) and calculations (Tolerance value as a fraction of the nominal value) are rounded to | |||

| | … significant digits | Number of significant digits if the first significant digit is not '1'. See also More > Terms > Numerical precision | 3 |

| | … significant digits if the first relevant digit is a '1'. | Number of significant digits if the first significant digit is '1'. See also More > Terms > Numerical precision | 4 |

| Option | Function | Default setting | |

|---|---|---|---|

| | Create numerical values with at least … | When creating a characteristic (read in or calculate), the numerical values for the nominal dimension, the upper tolerance and the lower tolerance are created with a minimum number of n decimal places. This means missing digits up to the specified number are filled with zeros, example: “1.5” ⇒ “1.500”. The number of places after the decimal point is not exceeded, example: “0.3333” ⇒ “0.3333”. | |

| | … decimal places. | 3 | |

| | Convert angles to decimal values on creation | Specifies that numerical values read in the sixty system are converted to decimal values when stamping. Example: 1°30' → 1.5°. Note Available from program version 4.3.0. | |

Valid as of program version 3.0.0:

| Option | Function | Default setting | |

|---|---|---|---|

| | Word specifications (texts) | Defines when and if word specifications are to be created: • Create only for single stamping\ • Always create • Never create | Create only for single stamping |

| | Other attributive characteristics | Defines when and if other attributive characteristics are to be created: • Create only for single stamping\ • Always create • Never create | Always create |

Valid until program version 2.10.3:

| Option | Function | Default setting | |

|---|---|---|---|

| Attributive characteristics are | |||

| | always created | Specifies that attributive characteristics are always created when stamping. | |

| | Ignored when stamping areas | Specifies that attributive characteristics are ignored when stamping areas. | |

| | always ignored | Specifies that attributive characteristics can not be stamped. | |

Note Available from program version 3.0.0.

| Option | Function | Default setting | |

|---|---|---|---|

| | Characteristics with nominal dimensions zero | Defines when and if characteristics with nominal dimensions zero are to be created: • Create only for single stamping • Always create • Never create | Create only for single stamping |

| | Auxiliary dimensions | Defines when and if auxiliary dimensions are to be created: • Create only for single stamping • Always create • Never create | Create only for single stamping |

| | Auxiliary dimensions: Use tolerance tables | Specifies that auxiliary dimensions are generally tolerated. | |

| | Theoretically exact dimensions | Specifies when and if theoretically exact measurements are to be created: • Create only for single stamping • Always create • Never create | Create only for single stamping |

| | Theoretically exact dimensions: Use tolerance tables | Specifies that theoretically exact dimensions are generally tolerated. | |

| | Rough dimensions | Specifies when and if rough dimensions are to be created: • Create only for single stamping • Always create • Never create Note Available from program version 4.3.0. | Always create |

| | Rough dimensions: Use tolerance tables | Specifies that theoretically exact dimensions are generally tolerated. Note Available from program version 4.3.0. | |

| | Control dimensions | Specifies when and if control dimensions are to be created: • Create only for single stamping • Always create • Never create Note Available from program version 4.3.0. | Always create |

| | Dimensions without tolerance entry at nominal dimension | Defines when and whether dimensions are to be created without tolerance entry at the nominal dimension: • Create only for single stamping • Always create • Never create | Always create |

| | Other variable characteristics | Defines when and if other variable characteristics are to be created: • Create only for single stamping • Always create • Never create | Always create |

| | Not indicated limit = 0 | Defines that the tolerance value 0 is set when creating a characteristic if the limit deviation is not specified in the drawing entry. Example: For 10 +0.1, 0.0 is set for the lower tolerance. Note Available from program version 4.1.9. | |

Note As of program version 3.0.0, the setting located in “Variable Characteristics” group.

| Option | Function | Default setting | |

|---|---|---|---|

| Attributive characteristics are | |||

| | always created | Specifies that word specifications are always created when stamping. | |

| | Ignored when stamping areas | Specifies that word specifications are ignored when stamping areas. | |

| | always ignored | Specifies that word specifications can not be stamped. | |

Note As of program version 3.0.0, the setting located in “Variable Characteristics” group.

| Option | Function | Default setting | |

|---|---|---|---|

| Characteristics from measurements without tolerance entry directly at nominal dimension are | |||

| | always created | Specifies that measurements without entry of the dimensions (e.g. ±0.1) or tolerance class (e.g. H7) are always stamped directly at the nominal dimension. | |

| | ignored when stamping areas | Specifies that measurements without entry of the dimensions (e.g. ±0.1) or tolerance class (e.g. H7) are ignored when stamping an area directly at the nominal dimension. | |

| | always ignored | Specifies that measurements without entry of the dimensions (e.g. ±0.1) or tolerance class (e.g. H7) can not be stamped directly at the nominal dimension. | |

| Option | Function | Default setting | |

|---|---|---|---|

| | Create limit value as nominal value | Stipulates that the value entered is interpreted as untoleranced nominal value. Upper and lower tolerances are given zero values. | |

| | Create nominal value with upper and lower tolerances | Stipulates that the value entered is interpreted unilaterally as generally toleranced nominal value (with added entry 'min.': upper tolerance = tolerance value; with added entry 'max.': lower tolerance = tolerance value). In each case the remaining tolerance is given a value of zero. | |

| | Create nominal value and limit value as tolerances | Stipulates that the value entered is interpreted as both nominal value and maximum value (with added entry 'max.': lower tolerance = value) or minimum value (with added entry 'min.': upper tolerance = value). | |

| | Create limit value only | Stipulates that an upper limit value (“max.”) is interpreted as upper tolerance and a lower limit value (“min.”) as lower tolerance. The nominal value and the remaining tolerance in each case are given a value of zero. | |

| | Ignore added entry “min./max.” | Stipulates that the added entry “min.” or “max.” is ignored and the value entered is interpreted as generally toleranced nominal value. | |

| | Do not apply zero values in characteristic | Stipulates that the zero values mentioned above are not applied in the “nominal value”, “upper tolerance” or “lower tolerance” fields. | |

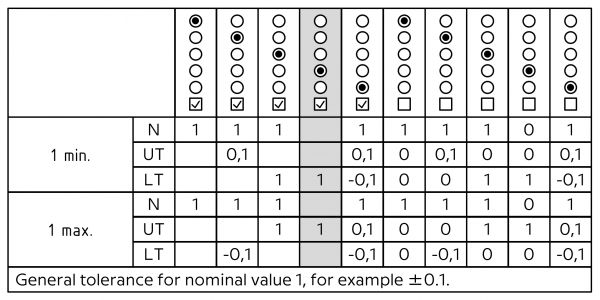

Possible settings based on an example, default setting highlighted in gray:

Note As of program version 3.0.0, the setting located in “Variable Characteristics” group.

| Option | Function | Default setting | |

|---|---|---|---|

| Characteristics with nominal dimensions zero are | |||

| | always created | Specifies that characteristics with the nominal dimensions zero (e.g. with increasing dimensioning and coordinate dimensioning) are always created when stamping. | |

| | Ignored when stamping areas | Specifies that characteristics with the nominal dimensions zero (e.g. with increasing dimensioning and coordinate dimensioning) are ignored when stamping areas. | |

| | always ignored | Specifies that characteristics with the nominal dimensions zero (e.g. with increasing dimensioning and coordinate dimensioning) can not be stamped. | |

| Option | Function | Default setting | |

|---|---|---|---|

| Create angular measurements as | |||

| | variable characteristic | Specifies that angular measurements are automatically created as a variable characteristic. | |

| | attributive characteristic | Specifies that angular measurements are automatically created as an attributive characteristic. | |

| Option | Function | Default setting | |

|---|---|---|---|

| | Generate individual characteristics from dimensionings with details of repetitions | Specifies that individual characteristics are created in the list of characteristics according to the number of repetitions. | |

Note As of program version 3.0.0, the setting located in “Variable Characteristics” group.

| Option | Function | Default setting | |

|---|---|---|---|

| Auxiliary measurements are | |||

| | always created | Specifies that auxiliary measurements are always created when stamping. | |

| | Ignored when stamping areas | Specifies that auxiliary measurements are ignored when stamping areas. | |

| | always ignored | Specifies that auxiliary measurements can not be stamped. | |

| | Use tolerances | Specifies that tolerance specifications are assigned to auxiliary dimensions. | |

Note As of program version 3.0.0, the setting located in “Variable Characteristics” group.

| Option | Function | Default setting | |

|---|---|---|---|

| Theoretically precise measurements are | |||

| | always created | Specifies that theoretically precise measurements are always created when stamping. | |

| | Ignored when stamping areas | Specifies that theoretically precise measurements are ignored when stamping areas. | |

| | always ignored | Specifies that theoretically precise measurements can not be stamped. | |

| | Use tolerances | Specifies that theoretically precise measurements are generally tolerated. | |

| Option | Function | Default setting | |

|---|---|---|---|

| Processing of shape and positional tolerances: | |||

| | Nominal dimension = width of the tolerance zone; upper tol. = 0; lower tol. = 0 | Specifies that the width of the tolerance zone is interpreted as the nominal dimension during stamping. | |

| | Nominal dimension = width of the tolerance zone; upper tol. = 0; lower tol. = (-1) x width of the tolerance | Specifies that the width of the tolerance zone during stamping is interpreted as the nominal dimension and as the lower tolerance value with a negative nominal dimension. | |

| | Nominal dimension = 0; upper tol. = width of the tolerance zone; lower tol. = 0 | Specifies that the width of the tolerance zone is interpreted as the upper tolerance value during stamping. | |

| | Nominal dimension = width of the tolerance zone; upper tol. = width of the tolerance zone; lower tol. = 0 | Specifies that the width of the tolerance zone during stamping is interpreted as the nominal dimension and as the upper tolerance value. | |

| | Nominal dimension = 0; upper tol. = (0,5) × width of the tolerance zone; lower tol. = (-0,5) × width of the tolerance zone | Specifies that the width of the tolerance zone is interpreted symmetrically divided as upper and lower tolerance value when stamping. Note Available from program version 4.4.5. | |

| | Zero values are not applied in the characteristic | Specifies that the zero values named above are not applied in the “Nominal dimension”, “Upper tolerance” / “Lower tolerance” fields. | |

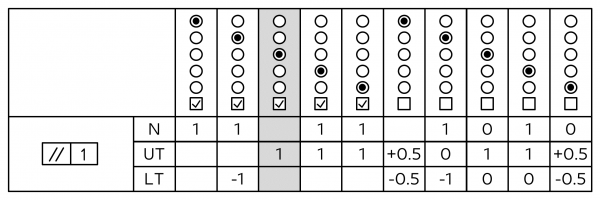

Possible settings based on an example, default setting highlighted in gray:

| Option | Function | Default setting | |

|---|---|---|---|

| Define radius dimension as | |||

| | “Radius” class | Radius dimensions automatically assign the “Radius” characteristic class. | |

| | “Rounding” class | Radius dimensions automatically assign the “Rounding” characteristic class. | |

| General tolerances used | |||

| | Table for roundings and chamfers | Use the table defined in the project settings for roundings and chamfers for generally tolerated rounding and chamfer dimensions. | |

| | Table for length dimensions | Use the table defined in the project settings for length dimensions for generally tolerated rounding and chamfer dimensions. | |

| Option | Function | Default setting | |

|---|---|---|---|

| Create chamfer as | |||

| | variable characteristic | Specifies that chamfers are created as a variable characteristic during stamping. | |

| | attributive characteristic | Specifies that chamfers are created as an attributive characteristic during stamping. | |

| Option | Function | Default setting | |

|---|---|---|---|

| | Value of the nominal size = 0 | Specifies that zero is entered for the nominal dimension. | |

| | Value of the not indicated limit = 0 | Specifies that when a characteristic is created, the value 0 is set for an unspecified limit. Example: For -0.3, 0.0 is set for the upper tolerance. Note Available from program version 4.1.9. | |

| Option | Function | Default setting | |

|---|---|---|---|

| | Nominal dimension = limit value; upper tol. = 0; lower tol. = 0 | Specifies that the limit value from the surface specification in the characteristic is set as the nominal dimension. | |

| | Nominal dimension = limit value; upper tol. = 0; lower tol. = (-1) x limit value | Specifies that the limit value from the surface specification in the characteristic is set as the nominal dimension and lower tolerance limit with negative sign. | |

| | Nominal dimension = 0; upper tol. = limit value; lower tol. = 0 | Specifies that the limit value from the surface specification in the characteristic is set as the upper tolerance limit. | |

| | Nominal dimension = limit value; upper tol. = limit value; lower tol. = 0 | Specifies that the limit value from the surface specification in the characteristic is set as the nominal dimension and upper tolerance limit. | |

| | Zero values are not applied in the characteristic | Specifies that the zero values named above are not applied in the “Nominal dimension”, “Upper tolerance” and “Lower tolerance” fields. | |

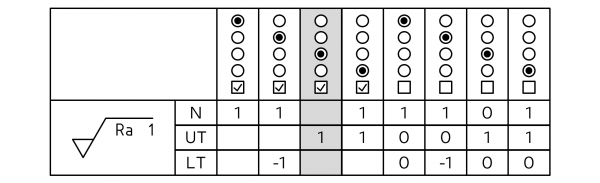

Possible settings based on an example, default setting highlighted in gray:

| Option | Function | Default setting | |

|---|---|---|---|

| | Simplified indications | The identifier (alpha and/or numeric) of a →simplified indications can be linked to the detailed indication in text form at this point. When stamping, such character strings (” key“) recognized in the drawing are replaced by a detailed specification (“value”) and evaluated accordingly. | x = Rz 4 y = Rz 25 z = Rz 100 |

| | Delete | Delete the line in question, together with its assignments, by clicking on the interface. | – |

| | Add | Add a new line, together with its assignments, by clicking on the interface. | – |

Go to previous page

Settings > Settings > General

Go to next page

Settings > Settings > Comparison